FUNA TECHNOLOGY ENGINEERING JOINT STOCK COMPANY

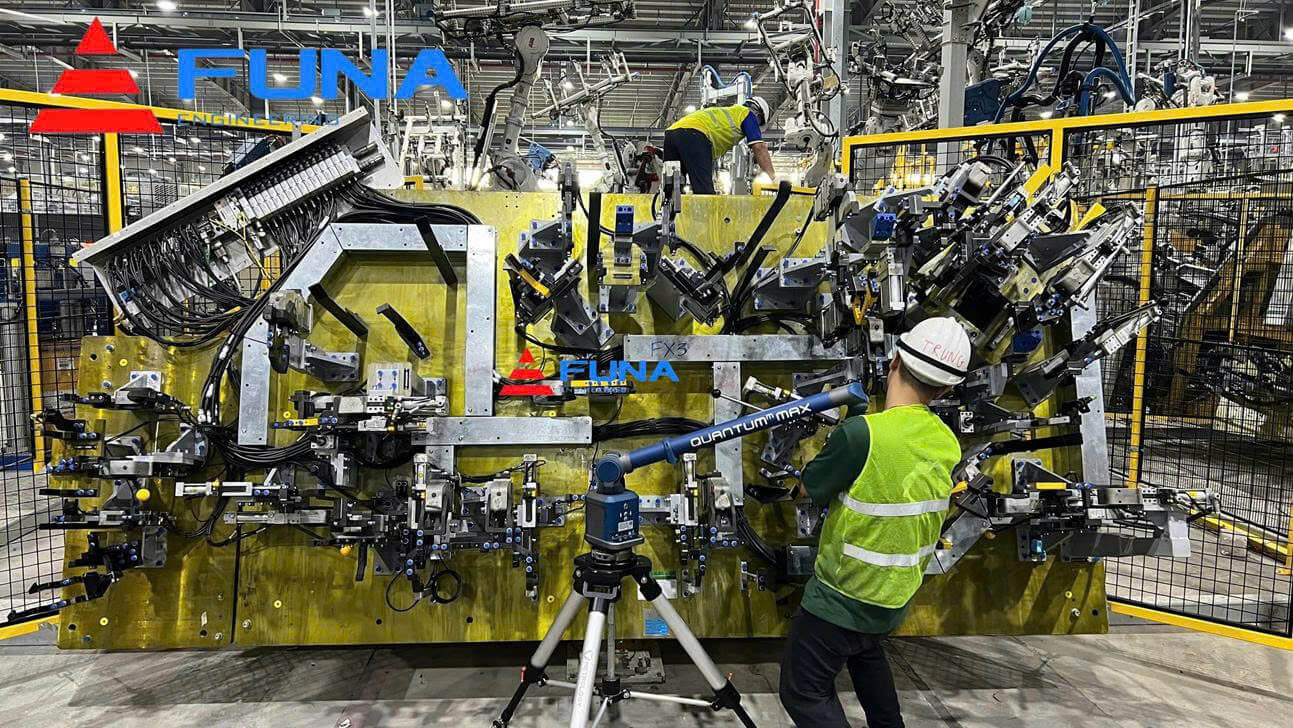

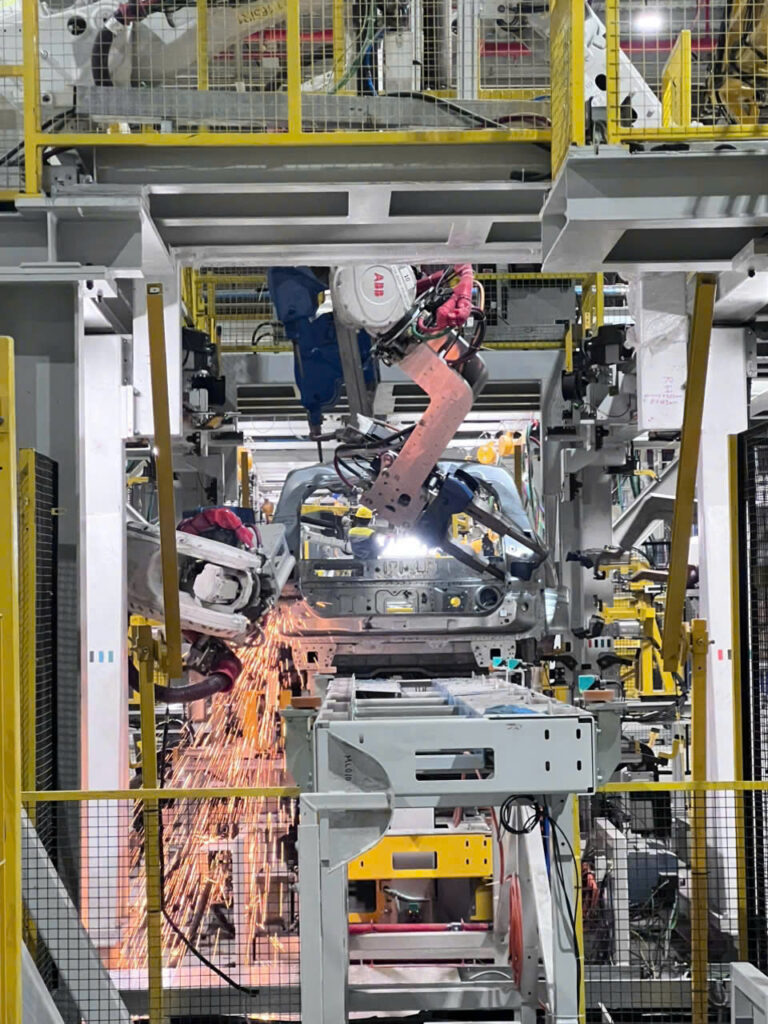

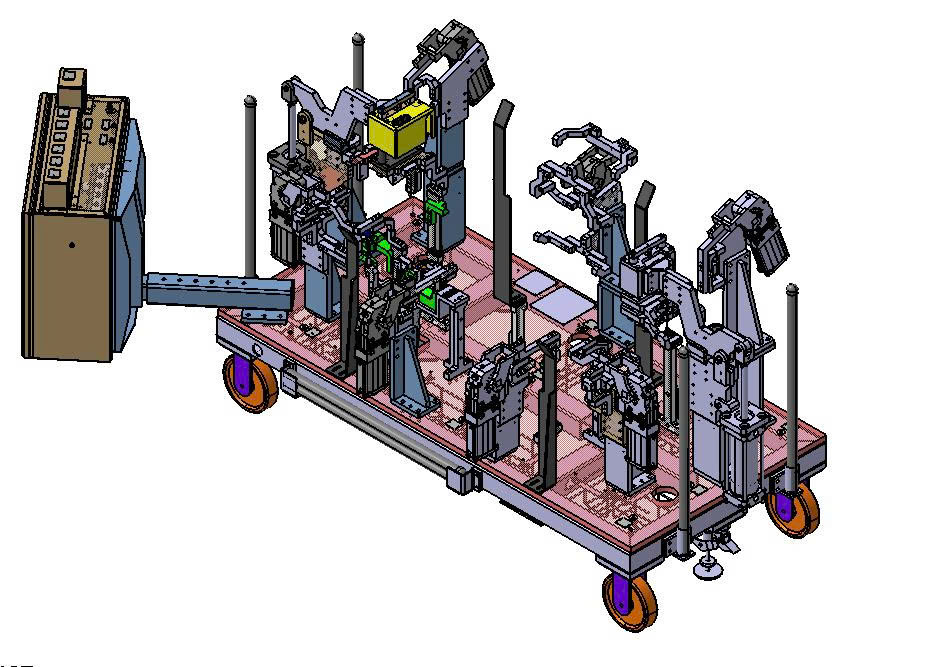

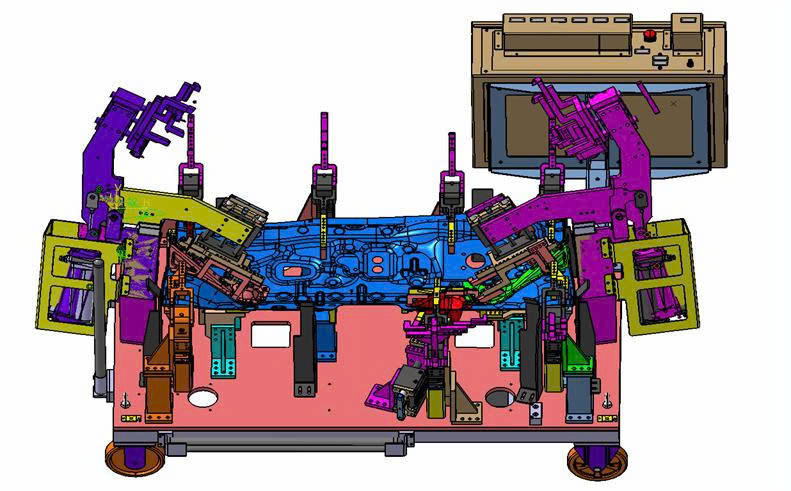

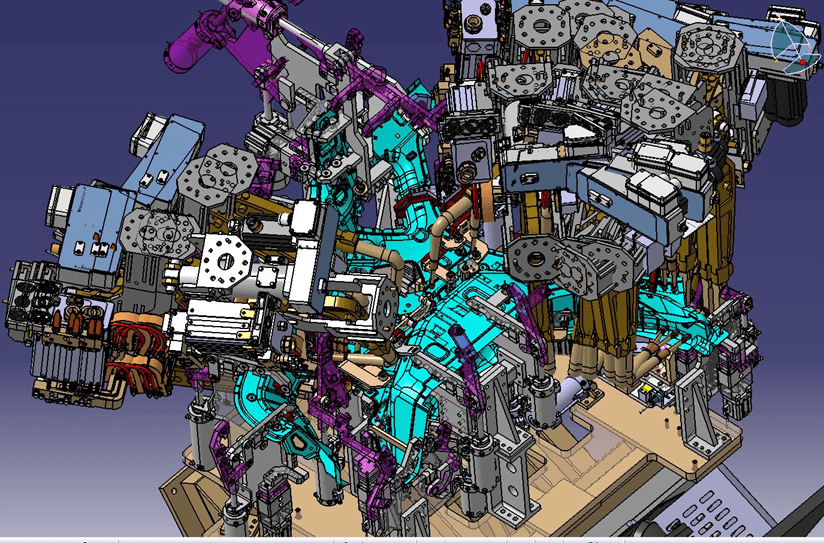

BODY-IN-WHITE (BIW) WELDING JIG AND FIXTURE DESIGN

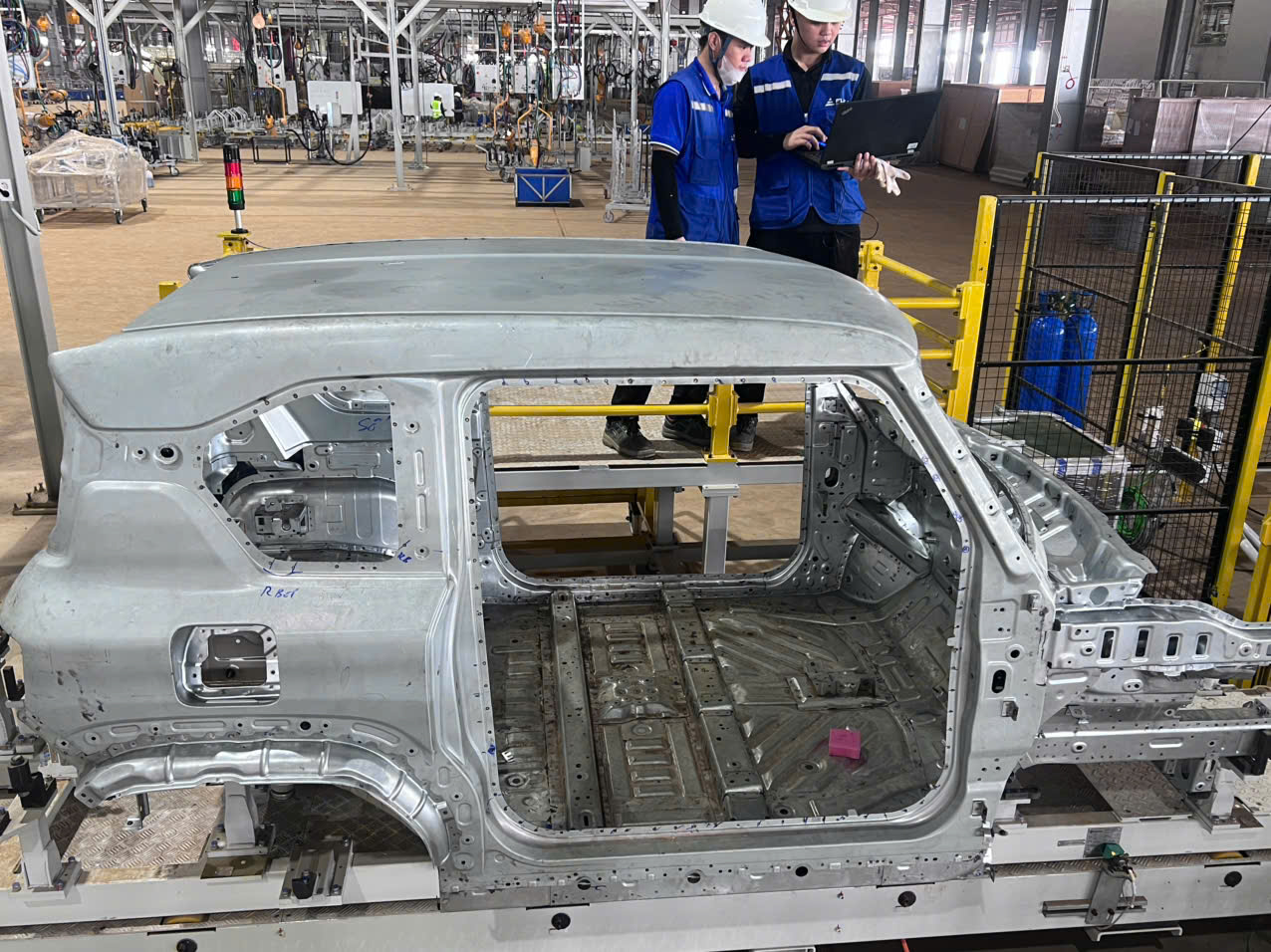

Funa specializes in the design and manufacture of Body-in-White (BIW) welding fixtures for the automotive industry, ensuring high precision, durability, and production stability. We have delivered BIW welding lines for projects in Vietnam as well as in international markets such as India and Indonesia,…

INDUSTRIAL MACHINERY DESIGN & MANUFACTORING

With a team of highly experienced mechanical engineers, we provide turnkey solutions covering design, machining, installation, and commissioning, delivering highly automated machinery systems with high accuracy and stable operation for continuous production.

HIGH-PRECISION MACHINING

Funa is one of the leading companies in Vietnam, specializing in the manufacture of high-precision mechanical parts and assemblies through multi-stage machining and technical processing processes, with strict quality control.

TECHNICAL EQUIPMENT FOR JIG AND MACHINERY SYSTEMS

We supply commercial equipment and components for production lines from reputable brands such as SMC, TUNKERS, and FESTO, which are carefully selected and integrated to fully meet the technical requirements, system compatibility, and operating conditions of each project.

OUR SERVICES

Vehicle Assembly Line

We provide comprehensive automotive assembly solutions, ranging from production line design, installation, and operation to technology transfer. Our services are tailored for factories manufacturing and assembling passenger cars, trucks, and various types of specialized vehicles.

Read More

Equipment Installation & Maintenance Services

We provide comprehensive automation solutions, ranging from PLC control system design and industrial robot programming to the integration of smart production lines. This service is suitable for manufacturing plants that need to optimize productivity, reduce labor, and enhance quality and stability.

Read More

Equipment Installation & Maintenance Services

We provide installation and maintenance services for industrial equipment and systems with a professional process, ensuring safety and stable operation. Our services are applied to factories, production workshops, automated lines, and technical projects.

Read More

Engineering Design Consulting & Solution Services

We provide optimal, creative, and tailored design solutions for each project, supporting clients from concept development, needs analysis, and design planning to detailed documentation and construction supervision. In addition, we offer specialized consulting services and deliver advanced technical solutions in the fields of mechanical engineering, automation, production lines, and industrial systems.

Welding Fixture Measurement & Inspection Services

We directly perform welding jig inspections at factories using a mobile 3D CMM measuring machine. Our welding jig inspection service provides precise solutions for checking, measuring, and calibrating welding jigs, fixtures, and tooling during the production process. With an experienced team of technicians and advanced measuring and inspection equipment, we are committed to ensuring accuracy, improving product quality, and optimizing machining processes.

Read MoreOPERATIONAL CAPACITY

OUR REAL PROJECTS

BUSINESS NEWS

MEDIA PROFILE

CONTACT FOR COLLABORATION

Email: contact@funavn.com

Hotline: (+84)0865.55.33.96

PARTNER